A Mini Review on Microbiological Quality of Commercial Fruit Juices in Pakistan

1The School of Life Sciences, Fujian Agriculture and Forestry University, Fuzhou 350002, China.

2Pakistan Science Mission (PSM), Noor Kot 51770, Pakistan.

3Department of Microbiology, 4Department of Wildlife and Ecology, University of Veterinary and Animal Sciences, Lahore

54000, Pakistan.

5Department of Zoology, Lahore College for Women University, Lahore 54000, Pakistan.

6Department of Zoology, University of Poonch, Rawalakot 12350, Azad Kashmir, Pakistan

7University College of Veterinary and Animal Sciences, The Islamia University of Bahawalpur, Bahawalpur 63100, Pakistan.

*Corresponding author:

Muhammad Naeem Iqbal;Email:

driqbalnaeem@hotmail.comViews 3055

Abstract

Fruit juices are considered to be the most preferred non-alcoholic beverage all over the world to all age groups. In general, microbial growth in fruit juice is restricted by using preservatives and also through other environmental factors during production. Still, some indicator organisms in fruit juice cause various food-borne diseases and even death. So, it is quite important to know the microbiological quality of the juices available in market with regard to public health. The quality control is established to ensure maximum production of safe products, so that it could serve the people in desired quality and quantity. Therefore, maintaining the quality of processed fruit juices is an important concern. So it is not only the responsibility of the food industry to provide safe and nutritious food to the public, but also the duty of government to see that industry is meeting its responsibility.

Keywords

Fruit juices, microbiological quality, bacterial contamination, public health.

Citation

Iqbal, M.N., Anjum, A.A., Wang, S., Ali, M.A., Ashraf, A., Yunus, F.N., Ali, S., Muhammad, A., Shahzad, M.I., 2016. A Mini Review on Microbiological Quality of Commercial Fruit Juices in Pakistan. PSM Microbiol., 01(1): 26-32.

Introduction

Various types of fruits and vegetables are grown in Pakistan with estimated annual production of 13.2 million metric tons. Globally, Pakistan is ranked as 6th producer of Kinoo, 5th for Mangoes (Sauco, 2002) and 36th for Apples. Mango known as ‘king of fruits’ is the fruit of excellence, mainly produced in Southern Asia and has a prominent position among the fruit juices grown in Pakistan.

The sweet orange was reported as the most economically important fruit in the world (Spiegel-Roy and Goldschmidth, 1996). In Philippines, citrus fruit juices are the most popular fruit products (Gabriel et al., 2006). In European countries, the orange juice was popular beverage (Fry et al., 1995).

Hygiene quality of fruits can be fairly judged by the abundance of microorganisms associated with them. The degree of contamination of fruit products largely depends on the initial load, source and kinds of microorganisms related to the fruits and care taken during collection, processing and product handling (Jay, 1991).

Fruit juices are rich in vitamins and minerals and are consumed for their nutritional qualities and refreshing character (USDA, 2003; Dosumu et al., 2009). Fruit juices have regulatory functions in the body and improves blood lipid profile in people affected by hyper-cholesterolemia (Kurowska et al., 2000). Fruit juices promote detoxification in the human body (Minich and Bland, 2007). Fruit juices are a good source of energy because increase the retention of magnesium, calcium and nitrogen in the body. Juice processing technologies should maximize these qualities. Juice is defined as the liquid extracted from the whole or cut fruit. Some fruits like apple, banana and mango yield little or no juice on squeezing rather the flesh obtained will result in dense puree and cannot be consumed directly. In case of lemon, extracted fluid is too sour to consume and used only after diluting with sugar and water. Juice extracted from the fruits is of great importance to human health because of its nutritional value (Macrae et al., 1997). Juice may be squeezed from crushed fruit material or directly extracted from the fruit (Matta, 2002).

Fruit juices contain water, carbohydrates, proteins, vitamins and minerals such as K, Fe, Zn, Ca and Mg and are food supplements (Okwu and Emenike, 2006). Fruit juices also play role in maintaining health and protect from heart diseases and cancer (Wenkam, 1990; Food Commission, 2009). Over the last decade packaged juice drinks have become more acceptable due to a number of factors such as convenience, low cost; environmental factors and manufacturers’ competition style (Marsh and Bugusu, 2007). However during the process of concentration may alter the nutritional value of the juice drinks (Lee and Sohn, 2003). Fruit juice concentrates are an important ingredient in the manufacture of many packaged fruit juices (Hong and Wrolstad, 1990).

Fruit Juice industry in Pakistan

The fruit juice industry is considered one of the largest industries in Pakistan. Fruit juices, carbonated beverages, syrups, powder drinks and mineral water are the products of beverage industry. In this study our discussion is about fruit juices. In Pakistan, 24 fruit juice processing plants and a number of small scale processing units with 400,000 metric tons per annum estimated capacity (SMEDA, 2007). Fruit juice industry is also facing some potential barriers such as, the use of inconvenient packaging material, low percentage of real fruit juice and lack of awareness about the standards for manufacturing.

In Pakistan, freshly prepared juices are generally used. These juices are extracted using blender or squeezing machine. The use of packed juices is also increasing with the trend of fast foods. These juices are prepared by mechanical processes and then preserved by physical means using tetra packs and other packaging materials. Juices may be directly obtained from fruits and may be prepared from concentrates. These may be unpasteurized or pasteurized and packed aseptically. Recently, ultra-high pressure technology is used to produce pasteurized fruit juices. The unlabelled and highly adulterated juices are more common because these are much cheaper than natural fruits. Major types of juices commonly used include, isotonic beverages, nutritional beverages, energy beverages, herbal beverages, nutraceutical beverages, smart beverages and fun beverages.

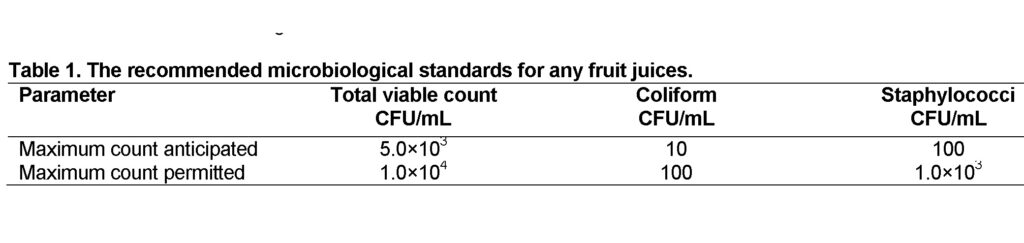

Recommended microbiological standards

Pakistan Standard Quality Control Authority (PSQCA) is working on certain regulations regarding registration of products and carrying a safety logo on the package. Punishment in the form of fine and imprisonment is also announced. There are some International satndards as well for fruit juices. Gulf standards, Codex standards which are to be followed during the manufacture process to assure the quality of juices (Codex Stan., 2005; Gulf Stan., 2000) (Table 01).

Production of fruit juices

Various raw materials are used for manufacturing fruit juices such as fruit pulp, citric acid, sugar, food color, preservatives and artificial flavors. Molasses are used to thicken the juices but it must be avoided. Fruit pulp is the major component of the high quality juice. Mango pulp is used as fillings for fruit juices and drinks (Hussain et al., 2003).

Fruit juice production should be done using standardized process. There may be some differences in type of technology depending upon the type of the fruit juice to be prepared and the conditions of the processing. The general flow of the manufacturing process is; at first the fruit pulp is boiled and transferred to the storage tank, then transferred to the sugar hopper. The mixing of the pulp and ingredients is done and is sent to syrup storage tank. Fruit juice preparation is stored in storage tank. After that the contents are filled and packaged. Packaged juices are cooled and stored.

Shelf life of fruit juices

The main objective of processing is to preserve the fruit or fruit juice in a stable form to supply to local and distant markets. The shelf life of the fruit juice depends upon the packaging material used and a lot of research work has been done on this topic (Zerdin et al., 2003). Imported juice products are packed using good quality packing material unlike that local products have poor quality packing materials and lack proper labeling. Juices should have labels indicating the shelf life of the products. Most of the imported juices have labels indicating their shelf life. Shelf life of the juice products also depend upon volume of the pack. Normally juices in 250ml packs have shelf life less than 6 months while the juices that are in larger packs have shelf life from 6 months to 1 year.

The main factors that contribute shelf life are quality and quantity of preservative and conditions of the production process. Several factors encourage, prevent or limit the growth of microorganisms in juices; the most important are pH, hygienic practice and storage temperature and concentration of the preservative. Storage of products at refrigerator temperature or below is not always best for the maintenance of desirable quality of some fruits. The growth of the pathogens can be favoured by changing pH of the juice products (FDA, 2001).

Use of processed fruit juices

In the developed countries the trend is shifting to the use of processed juices rather than fresh juices. Processed juices have more nutritional contents and are available and consumed easily. Orange juice is rich in vitamin C, so it is most appreciated and consumed among orange juices. The parametres like colour, flavour and the evolution of vitamin C during storage determine the quality and shelf life of the orange juice (Zerdin et al., 2003). Vitamin C take part in prevention of many diseases because it has high antioxidant power (Tannenbaum et al., 1985).

The storage conditions play a vital role in the stability of vitamin C, it is lost during poor storage conditions due to its oxidation (Kabasakalis et al., 2000). The factors that are responsible for loss of vitamin C are temperature, dissolved oxygen and oxygen barrier (Tannenbaum et al., 1985). The quality of the product during shelf life and its cost are also contributing factors.

Packaging of fruit juices

Now a day’s trend is shifting toward the use of Polyethylene Terephthalate (PET) packing because it has good mechanical features, clearness, UV resistance and provide oxygen barrier. This type of packing has been recommended for liquid foods (Zygoura et al., 2004). Various parametres should be noted while selecting the packing material such as shelf life, storage temperature and cost of the product. The amount of oxygen in the pack is the major factor which is responsible for the spoilage of juice (Soares and Hotchkiss, 1999). Many researchers have investigated the effects of oxygen on the quality of juice such as deterioration of ascorbic acid, increased rate of browsing and the growth of bacteria and moulds (Soares and Hotchkiss, 1999).

The exposure of juice to oxygen is reduced by using high barrier materials in traditional methods without nitrogen flushing (Zerdin et al., 2003). Aromatic polyamides are also used to improve the gas barrier of PET (Hu et al., 2005). Oxygen scavengers are also used to reduce the oxygen content in fruit juices. Some solid foods and orange juices are packed in plastic bags using this method (Zerdin et al., 2003). Although multilayer PET packings that have low permeability to oxygen have been recommended by many authors but these are much costly (Siegmud et al., 2004). So the best way is to use low cost monolayer PET packings and the methods to reduce the microbial growth so as to make these foods safe for consumption.

Microbial contamination of fruit juices

Micro-organisms are contaminating the food items and are increasing food deterioration (Nelson, 1981). Micro-organisms such as bacteria, viruses, algae, etc, harm the food items, they are also found in wine and antibiotics (Calloway and Carpenter, 1981). Various bacteria such as Bacillus alvei, Bacillus polymyxa, Bacillus subtilis, Staphylococcus aureus, Pseudomonas aeruginosa,Klebsiella pneumonia, Enterobecterand Escherichia coli are found in fruit juices(Iqbal et al., 2015). Micro-organisms use human foods as source of their nutrients. They are causing food deterioration by increasing their numbers, produce enzymatic changes and contribute to flavor. So these microbes must be eliminated from the contaminated food to preserve it (Ahmed, 1991). Although fruit juices are acidic in nature, high moisture content favors the growth of bacteria and yeast. Normally at room temperature, alcoholic fermentation and oxidation of alcohol and fruit acid by yeast and mould take place (Macrae et al., 1997).

Many outbreaks of Salmonella spp. have been linked with the consumption of unpasteurized juices (Harris et al., 2003). Federal Analysis Critical Control Point Program has been implemented by the U.S. Food and Drug Administration to reduce microbial population from fruit juices by 5 log 10 cycles (Goodrich et al., 2005). One of the best methods for removing microbes from fruit juices is Pasteurization (Silva and Gibbs, 2001). Being most popular thermal pasteurization may damage the nutritional ingredients.

Preservation of fruit juices

In Pakistan, mostly chemical preservation is used because it is cheaper than other methods. In this method various chemical preservatives are used to inhibit the microbial growth, thus preventing the juices from spoilage. Most of the preservatives are used in combination because none of the single preservative is effective if used alone (Chipley, 1983). Among more commonly used preservatives are sodium benzoate and potassium meta bisulphate because they show better antimicrobial activity (Lueck, 1990). It is reported that sodium benzoate is effective against some yeast strains and spoilage causing organisms (Sofos et al., 1986). The maximum levels for these chemicals are 1000 mg/kg for sodium benzoate and 500 mg/kg for potassium meta bisulphate (Codex Standard, 2005). Emerging food borne diseases are due to the illegal use of these preservatives because microbes have developed resistance (Akinpelu, 2001).

Non thermal treatments have also been attempted to reduce the microbial population of fruit juices. Germicidal effect of Ultra violet light has been considered to combat various micro-organisms (Bintsis et al., 2000). Fruit juice processing plant surface, water and liquid foods were disinfected using 254 nm wavelength of UV light (Guerrero and Barbosa, 2005). This method is advantageous because no toxic waste products are formed during processing, certain organic contaminants are produced which can be removed easily. Also this method does not change the flavor and colour of the juice products. The expenditure of energy is also minimum (Keyser et al., 2008).

Thermal processing changes the color and also damages the nutritional contents (Choi and Nielson, 2005). UV light treatment maintains physical attributes of juices such as the color and aroma (Tran and Farid, 2004). In the modern era the demand of the people is safe and fresh like foods (Mittal and Griffiths, 2005). The need of the hour is to develop such technologies which retain the nutritional contents of foods. One of the methods is the high intensity pulsed electric field treatment that inactivates the pathogenic and spoilage microbes without damaging the flavor, color and nutrients (Cserhalmi et al., 2006). The combination of this technology with other methods seems to be more effective (Sobrino and Martin-Belloso, 2006).

The fluids are placed between two electrodes and high intensity electric pulses are applied to inactivate or reduce the microbial population. This method has been found to be effective against Salmonella spp. and E. coli in orange juices (Mosqueda et al., 2007). It is required that the data regarding microbial inactivation using this method should meet commercial standards (Liang et al., 2002). According to the limits set by U.S. Food and Drug Administration, the novel technologies should achieve 5 log 10 reductions of microorganisms (USFDA, 2002). By the development of better preservation methods it has become possible to supply good quality fruit juices to heavy populations.

Fruit juice intake and human illness

The consumption of raw and unpasteurized fruit juices has been associated with human illness in United States (Deroever, 1998). Salmonellosis, E. coli O157:H7 infections and enterotoxigenic E. coli were found to be associated with various fruits and vegetables. Various types of microorganisms are found on the surface of fruits before harvest and it depends upon the conditions (Brackett, 1999). Microbes associated with most vegetables are Gram negative bacteria whereas yeast are found dominating the surface of fruits due the low acidic pH of fruit tissue (Splittstoesser, 1987).

Various outbreaks of illness in humans has been reported to be associated with consumption of unpasteurized fresh fruit juices. In 1995, more than 60 visitors were affected due to the consumption of unpasteurized fresh orange juice contaminated with salmonella in Florida Theme Park, USA (Schmidt et al., 1997). In recent years, there are also reports of E. coli 0157:H7 and Salmonella infections (Centers for Disease Control, 1996) which have developed awareness about the pathogens present in fruit juices which were previously thought to be pathogen free due to their acidic nature. U.S. Food and Drug Administration have altered regulations labeling laws, to include warning labels on unpasteurized fruit juices. The interest about the development of effective methods to inactivate or kill microbes is also the part of these regulations.

Survival of bacteria in fruit juices

The growth and survival of bacteria is limited due to low pH of fruit juices. pH range for citrus juices is 2.2 to 2.6 which do not support the growth of spoilage bacteria. Orange juice has pH between 3.4 to 4.0 which supports the growth and survival of Lactobacillus spp. and Leuconostoc spp. Pathogenic bacteria can survive at pH as low as 2.5 (De Jonge et al., 2003). Abnormal flavor and color of juices have been reported by these bacteria. These bacteria cannot grow in concentrates because they have high sugar concentrations. The temperature which favors the growth of bacteria is also an important factor. When fruit juices are kept at normal temperatures it enhances the growth of acetic acid bacteria. Normally fruit juices are kept at moderate temperatures before refrigeration so it can increase the microbial population in the juices. During the processing, the use of high temperature evaporator killed most of the microbes, if some survive they are killed during freezing, the freezing process will preserve the ultimate survivors. Improper processing methods and unheigenic conditions are indicated by higher counts of microbes in fruit juices. So there should be few microbes in the frozen juice concentrates.

Indicator organisms

Coliforms are commonly called as indicator organisms for foods and water (Cabelli, 1978), are very rare in fruit juices. Sometime false positive results appeared but these are not human or animal fecal coliforms. Viability of coliforms in frozen concentrates is very little but these can survive in fresh juices. So there is no significance of coliforms in frozen juices as health hazard. Spores of some microbes such as Clostridium botulinum can survive these conditions. The need of the hour is to improve the sanitary conditions to rule out the probability of any coliforms in foods. It is also required to reduce the growth of lactic acid bacteria to prevent spoilage.

Spoilage of fruits and fruit juices

Fruit and fruit juices are generally contaminated with bacteria, often from insect damage. Fallen fruit thus be avoided were possible for all of the risks. Flavoring, water and other chemical are all potential sources of microbial contamination. Bacterial that have been associated with spoilage in fruit juice industries include Acetobacter, Bacillus spp, Clostridium spp, Gluconobacter, Lactobacillus, Leccuonostoc, Saccharobacter, Zymobacter and Zymomonas . Gluconobacter is common spoilage agent of fruit juices.

The types of spoilage associated with fruit drink includes flat sour by Bacillus thermoacidurans, butyric anaerobes by Clostridium butyricum and nonspore formers (mostly lactic acid types of bacteria) by yeast and moulds. Common food poisoning bacteria Salmonella breandercup, Salmonella enteritidis, Staphylococcus pyogenes, Clostridium welchii, Clostridium botulinum, Vibrio parahaemolyticus and Bacillus cereus. Acid forming microaerophilic bacteria such as the lactobacilli tolerate lower pH values down to 3.5 in the case of some strains (De Jonge et al., 2003).

Fruit juices and antibiotic resistance

The emergence of bacteria resistant to most of the commonly used antibiotics is of great medical significance (Khan and Malik, 2001) because of the public health threats. Study of the antibiotic resistance of isolated strains of Staphylococci and Escherichia coli from foodstuffs is of utmost importance to public health workers, veterinarians, food microbiologists and those interested in bacterial zoonosis. The constant exposure of the body flora of man and animals to antibiotics has led to the selection and wide dissemination in human populations of antibiotic-resistant strains of bacteria. The incidence of bacterial resistance among bacteria isolated from food materials, sewage and water is reported several times (Khan and Malik, 2001; Malik and Ahmad, 1994). Manie et al. (1999) reported high incidence of multiple antibiotic resistant (MAR) pathogenic bacteria in unpasteurized and pasteurized packaged milk. These resistant bacteria can be transferred to humans through the consumption of milk, fruit juices and other foods, thus making it difficult to treat the resultant food-related infections.

The use of antibiotic(s) after the intake of the organism(s) may not be effective as the organisms may be susceptible or resistant to it. Resistance to antibiotics in foodborne pathogens may create problems for disease or illness treatment while antibiotic susceptibility leads to healing of the illness which the organism(s) caused. An increase in the incidence of multidrug-resistant Salmonella has been reportedin Ethiopia (Wolday, 1998).

The foods of animal origin and contaminated foods have been implicated with epidemics. The magnitude of the problem could be better understood if we have knowledge about the resistance in bacterial and animal species and by this we can take proper actions (Caprioli et al., 2000).

Conclusion and Recommendations

It is required to maintain the quality of natural products within standard limits, and the producers should be registered. Generally quality control is concerned with the inspection of raw materials, those materials which are in process and the finished products. Sometime only inspection of the finished products is done which makes the quality control an inspection.

It is the attribute of a good control system to reject substandard ingredients before the process begins and once, it has begun, prevents wastage of good raw material. Therefore, maintaining the quality of processed fruit juices is an important concern. So it is not only the responsibility of the food industry to provide safe and nutritious food to the public, but also the duty of government to see that industry is meeting its responsibility.

Acknowledgement

The authors are highly thankful to Prof Dr Aftab Ahmad Anjum, Department of Microbiology, University of Veterinary and Animal Sciences, Lahore, for technical support during this research work. The authors acknowledge that this work is from student thesis submitted in Higher Education Commission (HEC), Pakistan.

Conflict of Interest

The authors declare that this article content has no conflict of interest.

References

Ahmed S., Wedziche, B.L., Zeb, A., 1991. Reactivity of food preservation in disposed system, Royal Society of Chemistry, pp. 105-115.

Akinpelu, D.A., 2001. Antimicrobial activity of Anacardium occidentale bark. Fitoterapia., 72(3): 286-287.

Bintsis, T., Litopoulou-Tzanetaki, E., Robinson, R., 2000. Existing and potential applications of ultraviolet light in the food industry. A critical review. J. Sci. Food and Agri., 80(6): 637-645.

Brackett, R.E., 1999. Incidence, contributing factors, and control of bacterial pathogens. Postharvest Biol. Technol., 15(3): 305-311.

Cabelli, V.J., 1978. Obligate anaerobic bacterial indicators. In Indicators of Viruses in Water and Food (ed. G. Berg), Ann Arbor Science, Ann Arbor, MI. pp. 171-200.

Calloway, D.H., Carpenter K.O., 1981. Nutrition and Health, Saunders College Publishing, USA, p. 520-525.

Caprioli, A., Busani, L., Martel, J.L., Helmuth, R., 2000. Monitoring of antibiotic resistance in bacteria of animal origin. epidemiological and microbiological methodologies. Int. J. Antimicrob. Agents., 14(4): 259-301.

Center for Disease Control. 1996. Outbreak of Escherichia coli O157:H7 infections associated with drinking unpasteurized commercial apple juice. British Columbia, California and Washington, MMWR Morb. Mortal. Wkly. Rep., 45: 975.

Chiply, J.R., 1983. Sodium benzoate and benzoic acid, In: Antimicrobials in Foods (Eds.), A.C. Branen and P.M. Davidson. Marcel Dekker Inc., New York, USA, p. 16.

Choi, L.H., Nielsen, S.S., 2005. The effect of thermal and non-thermal processing methods on apple cider quality and consumer acceptability. J. Food Qual., 28(1): 13-29.

Codex Stan., 2005. Codex general standard for fruit juices and nectars. 247: 1-19. www.codexalimentarius.net/

Cserhalmi, Z., Sass-Kiss, A., Toth-Markus, M., Lechner, N., 2006. Study of pulsed electric field treated citrus juices. Inno. Food Sci. Emerg. Technol., 7(1-2): 49-54.

De Jonge, R., Takumi, K., Ritmeester, W.S., Leusden, F.M., 2003. The adaptive response of Escherichia coli O157 in an environment with changing pH. J. Applied Microbiol., 94(4): 555-560.

Deroever, C., 1998. Microbiological safety evaluation and recommendations on fresh produce. Food Control, 9(6): 321-347.

Dosumu, O.O., Oluwaniyi, O.O., Awolola, G.V., Okunola, M.O., 2009. Stability studies and mineral concentration of some Nigerian packed fruit juices, concentrate and local beverages. Afr. J. Food Sci., 3(3): 82-85.

FDA., 2001. Hazard analysis and critical control point (HACCP); procedures for the safe and sanitary processing and importing of juice; final rule. Fed. Regist., 66: 6138-6202.

Food Commission, 2009. Food label fib. The Food Commission Research Charity 94 White Lion Street, London N1 9PF. United Kingdom.

Fry, J., Martin, G.G., Less, M., 1995. Authentication of orange juice. In Production and Packaging of Non-Carbonated Fruit Juices and Fruit Beverages (P.R. Ashurt, ed.) Blackie Academic and Professional, New York, NY. pp. 1-52.

Gabriel, A.A., Tiangson-Bayaga, C.L.P., Fernandez, C.P., 2006. Consumer acceptance of Philippine orange drink as an iron fortified beverage for Filipino women. Food Sci. Technol. Res., 11(3): 269-277.

Goodrich, R.M., Schneider, K.R., Parish, M.E., 2005. The juice HACCP program: An overview. Food Safety and Toxicology Series, FSHNO5-15: 1-4. Institute Food and Agricultural Sciences, University of Florida.

Guerrero-Beltran, J.A., Barbosa-Canovas, G.V., 2005. Reduction of Saccharomyces cerevisiae, Escherichia coli and Listeria innocua in apple juice by ultraviolet light. J. Food Process. Engin., 28(5): 437-452.

Gulf Stan., 2000. Microbiological criteria for foodstuffs, Part 1. GCC, Riyadh, Saudi Arabia.

Harris, L.J., Farber, J.N., Beuchat, L.R., Parish, M.E., Suslow, T.V., Garrett, E.H., Busta, F.F., 2003. Outbreaks associated with fresh produce. Comp. Rev. Food Sci. Food Saf., 2(Suppl. 1), 78-141.

Hong, V., Wrolstad, R.E., 1990. Characterization of anthocyanin-containing colorants and fruit juices by HPLC/photodiode array detection. J. Agric. Food Chem., 38(3):698-708.

Hu, Y. S., Prattipati, V., Mehta, S., Schiraldi, D.A., Hiltner, A., Baer, E., 2005. Improving gas barrier of PET by blending with aromatic polyamides. Polymer, 46(8): 2685-2698.

Hussain, S., Rehman, S., Randhawa, M.A., Iqbal, M., 2003. Studies on Physico-chemical, microbiological and sensory evaluation of mango pulp storage with chemical preservatives. J. Res. (Sci.), BZ Uni., Multan, Pak., 14(1): 01-09.

Iqbal, M.N., Anjum, A.A., Ali, M.A., Hussain, F., ALI, S., Muhammad, A., Irfan, M., Ahmad, A., Irfan, M. and Shabbir, A., 2015. Assessment of microbial load of un-pasteurized fruit juices and in vitro antibacterial potential of honey against bacterial isolates. Open Microbiol. J., 9: 26-32. DOI: 10.2174/1874285820150601E001.

Jay, J.M., 1991. Modern Food Microbiology, 4th edition. Chapman Hall, New York.

Kabasakalis, V., Siopidou, D., Moshatou, E., 2000. Ascorbic acid content of fruit juices and its rate of loss upon storage. Food Chem., 70(3): 325-328.

Keyser, M., Ilze, A., Muller, A., Frans, P., Cilliers, B., Wihann, N.B., Pieter, A., Gouws, A., 2008. Ultraviolet radiation as a non-thermal treatment for the inactivation of microorganisms in fruit juice. Inno. Food Sci. Emerg. Technol., 9(3): 348-354.

Khan, R.M.K., Malik, A., 2001. Antibiotic resistance and detection of β-lactamase in bacterial strains of Staphylococci and Escherichia coli isolated from foodstuffs, World J. Microbiol. Biotechnol., 17(9): 863-868.

Kurowska, E.M., Spence, J.D., Jordan, J., Wetmore, S., Freeman, D.J., Piche, L.A., Serratore, P., 2000. Cholesterol-raising effect of orange juice in subjects with hypercholesterolemia. Am. J. Clin. Nutr., 72: 1095-100.

Lee, J.H., Sohn, K.S., 2003. Effect of concentration methods on the quality of single and blend juice concentrates. J. Food Sci. Nutr., 8 (3): 225-229.

Liang, Z., Mittal, G.S., Griffiths, M.W., 2002. Inactivation of Salmonella Typhimurium in orange juice containing antimicrobial agents by pulsed electric field. J. Food Prot., 65(7): 1081-1087.

Lueck, F., 1990. Food applications of sorbic acid and its salts. Food Addit. Contam., 7(5): 711-715.

Macrae, R., Robinson, R.K., Sadler, M.J., 1997. Encyclopedia of Food Science, Food Technology and Nutrition, Academic Press Inc., p. 3422-3426.

Malik, A., Ahmad, M., 1994. Incidence of drug and metal resistance in E. coli strains from sewage water and soil, Chem. Environ. Res.,3: 3-11.

Manie, T., Brozel, V.S., Veith, W.J., Gouws, P.A., 1999. Antimicrobial resistance of bacterial flora associated with bovine products in South Africa. J. Food Prot., (USA), 62(6): 615-618.

Marsh, K., Bugusu, B., 2007. Food Packaging and its Environmental Impact. Food Tech. 04: 46-50.

Matta, F., 2002. Passion Fruit: A New Fruit Crop for Gulf Coast States, Deep South Fruit & Vegetable Growers Conference and Trade Show, Biloxi, Mississippi, Vegetable Press, 02: (11).

Minich, D.M., Bland, J.S. 2007. Acid-alkaline balance: role in chronic disease and detoxification. Altern. Ther. Health Med., 13(4): 62-65.

Mittal, G. S., Griffiths, M.W., 2005. Pulsed electric field processing of liquid foods and beverages. In D. W. Sun (Ed.), Emerging technologies for food processing. Boston: Academic Press. p. 99-139.

Mosqueda-Melgar, J., Raybaudi-Massilia, R.M., Martín-Belloso, O., 2007. Influence of treatment time and pulse frequency on Salmonella Enteritidis, Escherichia coli and Listeria monocytogenes populations. Int. J. Food Microbiol., 117(2): 192-200.

Nelson, P.E., Tressler, D.K., 1981. Fruit and Vegetable Juice Processing Technology, Ail Publishing Co. Inc., New York, pp. 342-370.

Okwu, D.E., Emenike, I.N., 2006. Evaluation of the phytonutrients and vitamin content of citrus fruits. Int. J. Mol. Med. Adv. Sci., 2(1): 1- 6.

Sauco, V.G., 2002. Magazine of Chronica Horticulturae. Int. Soc. Hort. Sci., 42: 14-17.

Schmidt, R.H., Sims, C.A., Parish, M.E., Pao, S., Ismail, M.A., 1997. A model HACCP plan for Small-Scale, Fresh-Squeezed (Not Pasteurised) Citrus Juice Operations. University of Florida Cooperative Extension Service. Circular No. 1179. Gainesville. pp. 20.

Siegmud, B., Derler, K., Pfannhauser, W., 2004. Chemical and sensory effects of glass and laminated carton packages on fruit juice products. Food Science and Technology, 37(4): 481-488.

Small and Medium Enterprise Development Authority, 2007. Government of Pakistan. Fruit Juice Manufacturing, Pre-Feasibility Study. pp. 24.

Soares, N.F.F., Hotchkiss, J.H., 1999. Comparative effects of de-aeration and package permeability on ascorbic acid loss in refrigerated orange juice. Packag. Technol. Sci., 12(3): 111-118.

Sobrino-Lopez, A., Martin-Belloso, O., 2006. Enhancing inactivation of Staphylococcus aureus in skim milk by combining high-intensity pulsed electric fields and nisin. J Food Prot., 69(2): 345-353.

Sofos, J.N., Pierson, M.D., Blocher, J.C., Busta, F.F., 1986. Mode of action of sorbic acid on bacterial cells and spores. Int. J. Food Microbiol., 3(1): 1-17.

Spiegel-Roy, P., Goldschmidth, E.E., 1996. Biology of Citrus, Cambridge University Press, Cambridge, England.

Splittstoesser, D.F., 1987. Fruits and fruit products. In: Beuchat LR (Ed), Food and Beverage Mycology. Van Nostrand Reinhold, New York, pp. 101-128.

Tannenbaum, S.R., Archer, M.C., Young, V.R., 1985. Vitamins and minerals. In O. R. Fennema (Ed.), Food chemistry, New York: Marcel Dekker. 2nd ed., pp. 488-493.

Tran, M.T.T., Farid, M. (2004). Ultraviolet treatment of orange juice. Inno. Food Sci. Emerg. Technol., 5(4): 495-502.

United State Department of Agriculture, 2003. Juice or fruit drink? Nibbles for health nutrition newsletters for parents of young children, Food and Nutrition Service, 1400 Independence Ave., S.W. Washington, DC 20250 USDA 1-2.

U.S. Food and Drug Administration, 2002. Exemptions from the warning label requirement for Juice-Recommendations for effectively achieving a 5-log reduction.

Wenkam, A., 1990. Utilization and processing of fruits. Macmillan Press, London. pp 388 -506.

Wolday, D., 1998. Increase in incidence of multidrug-resistant Salmonella in Ethiopia, J. Antimicrob. Chemoth.,41(3), 421-423.

Zerdin, K., Rooney, M.L., Vermue, J., 2003. The vitamin C content of orange juice packed in an oxygen scavenger material. Food Chem., 82(3): 387-395.

Zygoura, P., Moyssiadi, T., Badeka, A., Kondyli, E., Savvaidis, I., Kontominas, M.G., 2004. Shelf life of whole pasteurized milk in Greece: effect of packaging material. Food Chem., 87(1):1-9.